Products

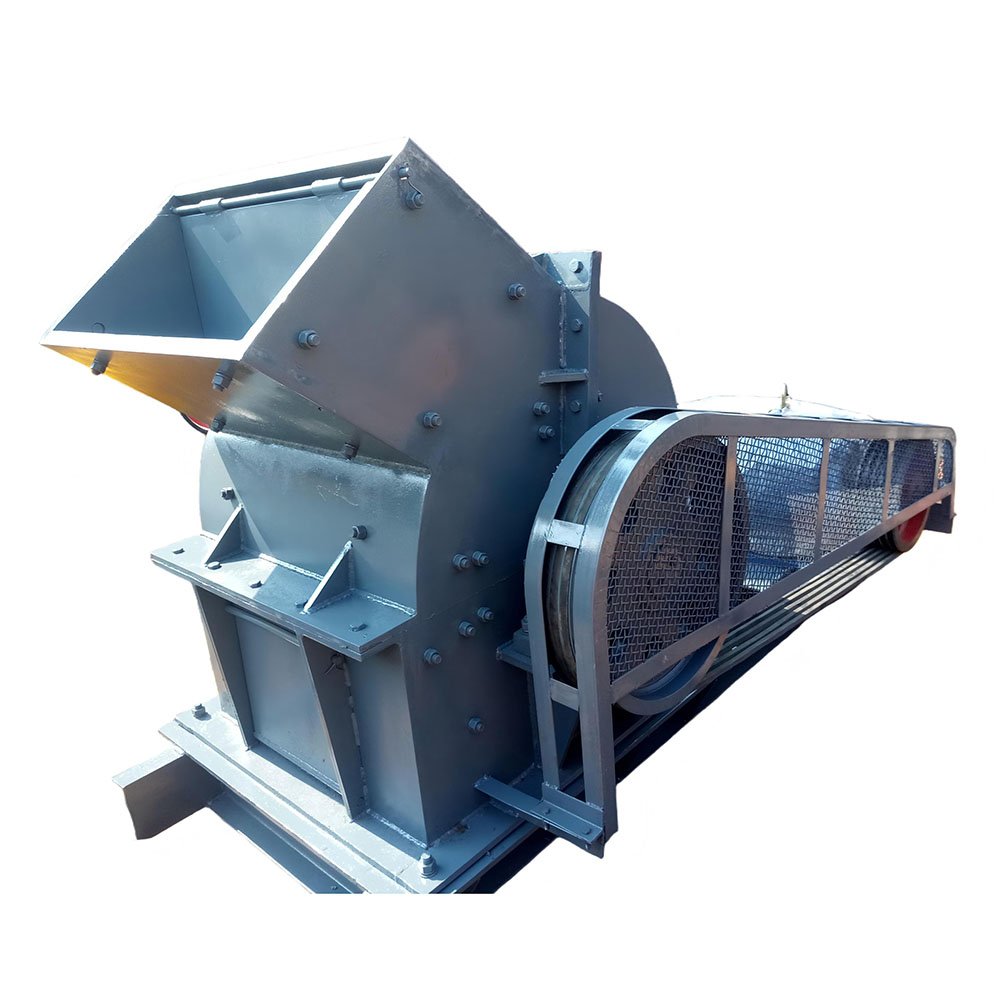

Crushing equipment serves as the core primary processing machinery for industries including mining, sand and gravel aggregates, metallurgy, and chemicals. It is primarily employed to progressively crush bulk raw ore, rock, construction waste, and similar materials into particle sizes suitable for subsequent processing or engineering applications. Common equipment includes jaw crushers, cone crushers, impact crushers, hammer crushers, and mobile crushing plants. Different types of crushing equipment operate on distinct principles, handle varying materials, and deliver specific particle size outcomes. Flexible selection based on raw material characteristics, production capacity requirements, and finished product specifications enables efficient, energy-saving, and stable crushing operations.

Sand-making equipment is utilised to further process crushed stone into artificial sand meeting construction sand standards, forming a vital component of aggregate production lines. Common equipment includes impact sand-making machines, vertical impact crushers, sand-making and shaping machines, and sand washers. Sand-making equipment offers advantages such as excellent particle shape, rational gradation, high output, and low energy consumption. It finds extensive application in sand and gravel quarries, concrete mixing plants, hydroelectric power stations, motorway construction, and other industries, supplying high-quality manufactured sand for engineering projects.

Mineral processing equipment is employed for the separation, purification and enrichment of materials such as metallic and non-metallic ores, constituting a critical component in the mining industry for achieving efficient resource utilisation. It primarily encompasses flotation machines, magnetic separators, gravity separation equipment, classifiers, ball mills, agitation tanks, thickeners and filters. Different mineral processing equipment employs distinct techniques—such as flotation, magnetic separation, gravity separation, and electrostatic separation—based on the physical and chemical properties of the material. This enables the efficient separation of various minerals including iron, copper, gold, silver, lead-zinc, manganese, tungsten, and tin. These processing units offer high separation precision, substantial enrichment ratios, and stable operation. Process configurations can be tailored to ore characteristics and plant scale, delivering economical, environmentally sound, and efficient mineral processing solutions for mining enterprises.

Grinding equipment is utilised to pulverise ores, non-metallic minerals, chemical raw materials, construction materials and other substances into fine or ultrafine powders, serving as the core apparatus within powder processing production lines. This primarily encompasses Raymond mills, high-pressure suspended roller mills, vertical grinding mills, ultrafine grinding mills, ball mills, and tube mills. Different grinding equipment types employ distinct grinding methods based on material hardness, moisture content, and fineness requirements, producing powder products ranging from tens of mesh to thousands of mesh. Characterised by high throughput, low energy consumption, and uniform particle size distribution, these grinding systems are extensively utilised across mining, metallurgy, construction materials, chemical, power generation, and refractory industries. They deliver efficient, stable, and scalable powder processing solutions for clients.

Production line equipment refers to integrated production systems comprehensively designed to meet the demands of industries such as aggregate processing, metal and non-metal mining, and construction waste recycling. These systems comprise multiple units including crushing, sand-making, screening, conveying, feeding, grinding, and mineral processing equipment, arranged in specific configurations. Common production line types include aggregate production lines, sand-making production lines, construction waste processing lines, mineral processing lines, and powder processing lines. These production lines feature high automation, stable operation, low energy consumption, and substantial output capacity. They can be custom-designed according to clients' raw material characteristics, site conditions, finished product requirements, and investment budgets, enabling continuous and intelligent production from raw materials to finished products.

Feeding and screening equipment serves as critical auxiliary machinery within production processes across mining, aggregate, building materials, and chemical industries. It fulfils dual functions of uniform material feeding and graded screening, constituting an essential component for ensuring continuous, stable, and efficient production line operation. Principal equipment includes vibrating feeders, belt feeders, circular vibrating screens, linear vibrating screens, high-frequency screens, and probability screens. Feeding equipment enables the quantitative and uniform conveyance of materials, ensuring stable feed supply to primary processing machinery. Screening equipment facilitates multi-stage classification of materials, effectively controlling final product particle size and enhancing product quality. Characterised by compact design, reliable operation, low energy consumption, and straightforward maintenance, feeding and screening equipment can be flexibly configured to meet diverse process requirements. It finds extensive application in crushing production lines, sand manufacturing lines, mineral processing operations, and industrial raw material handling systems.

Mobile crushing stations are integrated crushing and screening units designed for vehicle-mounted mobility. They consolidate feeding, crushing, screening, and conveying functions within single or multiple vehicle-mounted modules, enabling rapid on-site material processing and transfer. Primary types include jaw crusher mobile stations, impact crusher mobile stations, cone crusher mobile stations, sand-making mobile stations, and modular mobile screening stations. Mobile crushing plants offer significant advantages including high mobility, convenient relocation, rapid installation, advanced automation, and strong adaptability. They find extensive application in aggregate production, construction waste recycling, road construction and maintenance, and metal ore crushing. Through flexible configuration options, these plants can accommodate diverse raw materials, operating conditions, and finished product specifications, delivering efficient, environmentally sound, and cost-effective mobile crushing solutions for clients.